Learning Zone

Overcoming fleet management problems through better data management

Improving the management of your fleet and assets data can boost efficiency and create cost savings

Read our short blog to find out how…

Advances in technology means a likelihood that there’s more data available than ever. Whilst this can be overwhelming, the trick is to avoid information overload and source only the data you actually need to overcome your fleet management challenges.

The ability to gather and analyze data effectively can become an incredibly useful tool. By having a thorough knowledge of your asset data and how to utilize only the relevant information available will help you make the best, most informed decisions to support a wide range of operational improvements.

Accurate data can provide many benefits beyond scheduling, maintenance and budget forecasting. According to NTEA (The Association for the Work Truck Industry), correctly analyzed and compiled data can help you improve operations.

So, where do you start?

How data management helps fleets

To start, let’s look at why fleet-related data management is so useful to help you run an efficient operation.

Gathering appropriate information and analyzing it for benchmarking and improvement purposes is a good practice to help you solve fleet management challenges by building a constructive understanding of how your vehicles, equipment, other assets and employees operate. It can also help identify inefficiencies and support better operational decisions in areas such as:

Better vehicle utilization:

Accurate, real-time knowledge of the vehicles within your fleet, including how they are being allocated, used and disposed of, can help ensure ongoing utilization improvements.

Improved driver oversight and profiling:

Information about your drivers can help create risk profiles and identify training needs. This can, in some instances, help reduce accidents and fleet insurance premiums.

Enhanced parts management:

Knowledge of parts and stock availability can help eliminate overstock situations, increase staff/shop productivity, minimize downtime and ultimately reduce inventory costs.

Reduced fuel consumption and emissions:

Details of fuel costs, purchases, consumption and emissions can be useful when analyzing performances and ensuring compliance with legislative and other requirements.

Maintenance and repair activities:

Data concerning repair times and shop productivity can help assess how well your maintenance and repair operations are being run – and where improvements could be made. A well-run fleet maintenance department provides numerous benefits including reduced maintenance costs and vehicle downtime costs.

Did you know… with fuel expenditure accounting for around a third of the average fleet’s spending, reducing fuel consumption can lead to significant cost savings within your fleet.

What data do I need to manage my fleet?

There is a huge range of fleet-related information that can prove useful for fleet management. Such data is generated both internally (for example, via job cards and work rotas) and externally (e.g. from GPS or telematics software

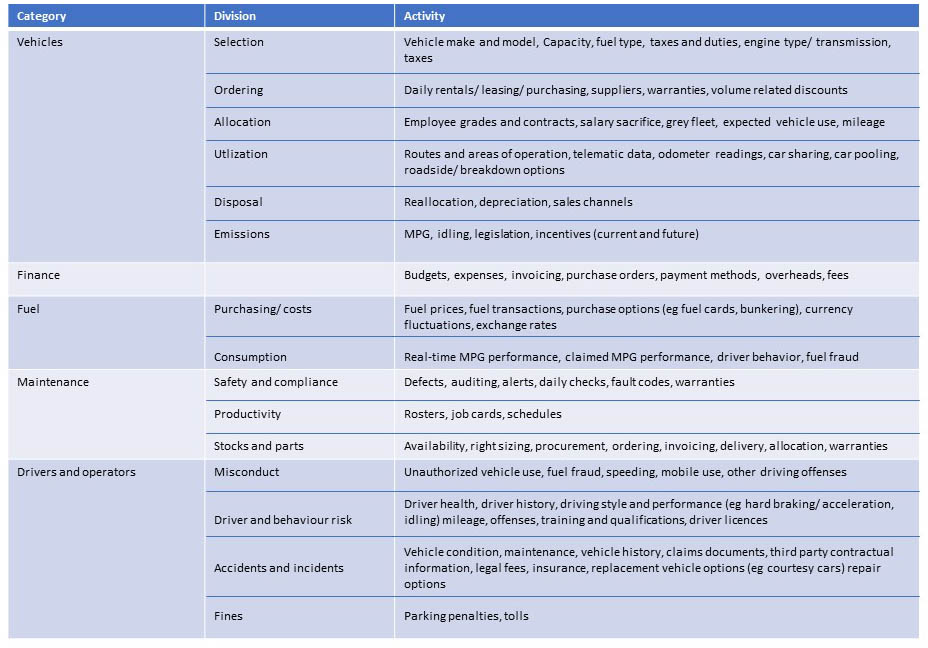

This table demonstrates areas for consideration when managing a fleet:

Overloaded and overwhelmed: a common problem

Ultimately, if an operation doesn’t understand or have solid control of its data, you’ll find that it’s a harder challenge to manage your fleet. The potential consequences of this can include stressed staff, costly mistakes and wasteful spending.

However, as you can see there’s a huge variety of things to consider: In fact, the sheer volume of data can often feel like you are sifting through a mountain of detail.

Recent research reveals that four out of five business decision-makers have carried out tasks outside of working hours to catch up on their workload. A staggering 88% of these claim that administrative tasks have caused unnecessary stress. Not good!

An important fact to consider is that just because you have a lot of data at your disposal, it doesn’t mean that you have to necessarily assess it all. Some data may simply not be relevant to help you meet your goals.

The best tactic for ensuring efficiency is to have an effective process in place for gathering only the data that’s useful for your unique fleet operation.

Gathering useful data

When it comes to gathering data that could be used to help manage your fleet, here’s three important steps to consider:

1. Assess what data you have available:

Data could be held in spreadsheets or existing fleet management systems. It can also be available via software systems such as your GPS or telematics, fuel management systems, accounting finance software or service, part or account providers. You may be able to use information from vehicle specification databases or databases containing information on licenses too.

It’s important to make sure that all your existing data is being used effectively – and the first step to achieving this is by gaining full awareness of what data you have available, what you actually need and how to find it quickly and easily.

2. Determine how your data can help improve your operation:

When it comes to understanding what data could be useful to you, it’s probably best to start with your core needs – the actual areas where effective data management can be crucial for your business.

One useful strategy is to identify your weaker areas and then determine how to fix them. Asking yourself questions such as “What are my fleet’s highest cost categories?” and “Which vehicles, systems or components are utilized most?” can help you identify areas that require focus. Then, consider what data could be beneficial when used for benchmarking and improvement.

For example, if your fuel costs are causing you concern, the ability to gather and analyze telematics data could help you identify drivers with a tendency for hard braking, acceleration or speeding which use more fuel. The ability to act on and monitor such behavior can help you reduce costs.

Using our own data as an example clearly demonstrates that the difference between the best and worst drivers can mean a 25% variance in fleet costs.

3. Understand your data:

Time is money! It’s important to have immediate access to your data and be able to interpret it quickly. Instead of using a system that requires you to look around for the data you need – through dated fleet management practices such as spreadsheets or paper-based filing systems – opt for a system that enables you to easily access all your data from a single location. From this instant comparisons can be created and reports that boost your understanding of what is happening in your fleet, and how it can be improved.

Following these processes will provide you with a solid start in understanding what data you have, what data you need and how it can be used to support positive changes.